|

The first step is to ready a wooden "blank." A blank is simply a small block of wood. It is cut to the rough width and length needed for the given pen. The centers are drilled out and a brass tube is inserted. |

|

|

With the brass tube in the blanks (two are required for each pen), the blanks are drilled out so that the wood is perfectly flush with the brass tubing--this ensures the pen pieces will be precisely the right size. |

|

The prepared blanks are then set into a mandrel which holds them in place on the lathe. The mandrel is then tapped into the chuck of the lathe and the tool rest is set up so that the first shaping can begin. |

|

A roughing gouge is utilized to transform the square block into a cylinder. |

|

Finer tools are used to shape the wood's curves. Here, the pen is a slimline with a slight arch to each piece. |

|

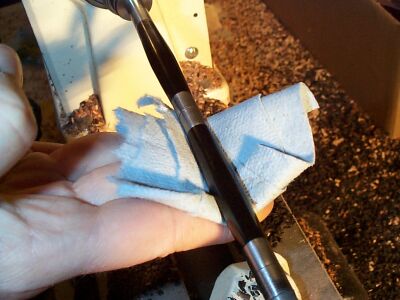

One the turning is completed, the wood is smoothed with a series of fine grit pads soaked in mineral spirits. |

|

The final step is to saturate the wood with a French polish and then buff it to a mirror-like sheen. |

|

The completed pen is ready to write the Great American Novel! |